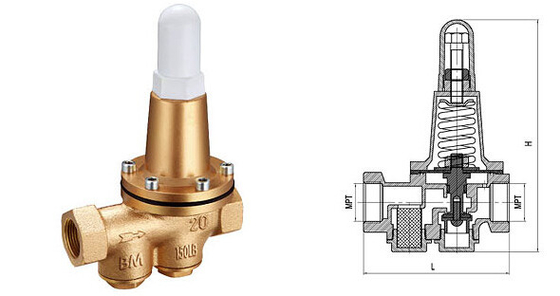

Proportional Water Pressure Relief Valve / Stainless Steel Pressure Release Valve

Water Pressure Relief Valve Introduction

The valves limits the flow rate in the pipeline to a preset rate, regardless of upstream pressure variations.

The valves is controlled by pilot valves, which takes use of integrated orifice plate to detect flow rate

represented by differential pressure, and the differential pressure is used to control the pilot valves to

implement flow rate control.

Water Pressure Relief Valve Main characteristics:

• Diaphragm: rubber+reinforced nylon

• Spring: stainless steel

• Screws: stainless steel

• Connecting: flanged ends

• Pressure loss < 0.10 bar (completely open)

• Pressure loss < 0.40 bar (with orifice)

• Pilots: Bronze

• Excess flow pilot: type three-ways differential pressure, spring adjustable on the spot,

material: bronze, in combination with a calibrated orifice disk

(made of stainless steel or plastic) for the differential pressure measurement,

Diaphragm type adjustable pressure reducing/sustaining valves is installed in feeding/draining water

system in high building to reduce the inlet pressure required pressure.

The valves ensure outlet pressure stay in the setting valves stably on its own energy,namely the outlet pressure does not change owing to the inlet pressure's and flow's change.

There is self-cleaning filtering mesh installed at the valves control system's inlet not to let the great specific gravity and large diameter particle flow in to the system and ensure the system is unimpeded.The valves acts quickly and has a long life.

Size from DN40 to DN600

Hydraulic valve for controling pressure and flow rate

(with an excess flow pilot and a pressure regulator pilot)

Main characteristics:

• Standard: EN ISO 9635-5:2014 and EN 14267:2004

• Body & bonnet: ductile iron, coated Epoxy 250 μm

• Diaphragm: rubber+reinforced nylon

• Spring: stainless steel

• Screws: stainless steel

• Connecting: flanged ends

• Pressure loss < 0.10 bar (completely open)

• Pressure loss < 0.40 bar (with orifice)

• Pilots: Bronze

• Excess flow pilot: type three-ways differential pressure, spring adjustable on the spot,

material: bronze, in combination with a calibrated orifice disk

(made of stainless steel or plastic) for the differential pressure measurement,

comprising the connecting to the hydraulic valve by PEHD pipes

(DN6-8-12mm according to the DN of the valve)

• Pressure regulator pilot: three-ways,

material: bronze, spring adjustable on the spot,

comprising the connecting to the hydraulic valve by PEHD pipes

(DN6-8-12mm according to the DN of the valve)

Medium: Water

| DN |

L |

D |

|

|

D1 |

|

|

D2 |

|

|

Z-~d |

|

|

H1 |

H |

| |

|

PN10 |

PN16 |

PN25 |

PN10 |

PN16 |

PN25 |

PN10 |

PN16 |

PN25 |

PN10 |

PN16 |

PN25 |

| 50 |

203 |

165 |

165 |

165 |

125 |

125 |

125 |

102 |

102 |

99 |

4-~18 |

4-~18 |

4-~18 |

137 |

95 |

| 65 |

216 |

185 |

185 |

185 |

145 |

145 |

145 |

122 |

122 |

118 |

4-~18 |

4-~18 |

8-~18 |

145 |

97 |

| 80 |

241 |

200 |

200 |

200 |

160 |

160 |

160 |

133 |

133 |

132 |

8-~18 |

8-~18 |

8-~18 |

178 |

109 |

| 100 |

292 |

220 |

220 |

235 |

180 |

180 |

190 |

158 |

158 |

156 |

8-~18 |

8-~18 |

8-~18 |

232 |

152 |

| 125 |

330 |

250 |

250 |

270 |

210 |

210 |

220 |

184 |

184 |

184 |

8-~18 |

8-~18 |

8-~18 |

286 |

152 |

| 150 |

356 |

285 |

285 |

300 |

240 |

240 |

250 |

212 |

212 |

211 |

8-~18 |

8-~18 |

8-~18 |

318 |

160 |

| 200 |

495 |

340 |

340 |

360 |

295 |

295 |

310 |

268 |

268 |

274 |

8-~18 |

12-~18 |

12-~18 |

413 |

220 |

| 250 |

622 |

395 |

405 |

425 |

350 |

355 |

370 |

320 |

320 |

330 |

12-~18 |

12-~18 |

12-~18 |

502 |

250 |

| 300 |

698 |

445 |

460 |

485 |

400 |

410 |

430 |

370 |

370 |

389 |

12-~18 |

12-~18 |

12-~30 |

600 |

372 |

| 350 |

787 |

505 |

520 |

550 |

460 |

470 |

490 |

430 |

430 |

448 |

16-~22 |

16-~26 |

16-~33 |

526 |

314 |

| 400 |

914 |

565 |

580 |

620 |

515 |

525 |

550 |

482 |

482 |

503 |

16-~26 |

16-~30 |

16-~36 |

570 |

340 |

| 450 |

787 |

565 |

580 |

620 |

515 |

525 |

550 |

482 |

482 |

503 |

16-~26 |

16-~30 |

16-~36 |

677 |

415 |

Main Technical Feature |

| Nominal Pressure |

1.0MPA |

1.6MPA |

2.5MPA |

|

| Test pressure of the shell |

1.5MPA |

2.4MPA |

3.75MPA |

|

| Sealed test pressure |

1.1MPA |

1.76MPA |

2.75MPA |

|

| Suitable temperature |

≤80℃ |

|

| Suitable medium |

water |

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!